Transform Your Team.

Transform Your Results.

At Total Team Transformation Consulting LLC, we build high-performing Lean cultures through expert coaching, digital innovation, and real-time Gemba leadership

The Journey from Lean Tools to Lasting Change

After 24 years of corporate leadership roles, I’ve walked a path few have seen fully: the journey from traditional Lean tools to true cultural transformation. Over my career, I worked with many Lean methodologies, consultants, and systems across global manufacturing operations, but I noticed a recurring problem: the improvements didn’t stick. Despite new tools and systems, the results were often temporary. Something deeper was missing. Through hard-earned lessons, I realized that lasting success doesn’t come from Lean tools alone, it comes from building people. True transformation happens when organizations develop daily habits of improvement.

Building High-Performing Cultures

Culture is not built in meetings; it’s built in routines, the right routines that grow thinking, problem-solving, and leadership capabilities at every level. Along the way, I immersed myself in mastering the power of developing people through simple, disciplined practices known as katas. I learned firsthand which routines work, and which ones fail, whether in small, agile teams or complex, multinational organizations. Today, I help companies avoid the traps I lived through. At Total Team Transformation Consulting, we don’t offer quick fixes, we partner with organizations to build high performing cultures where daily improvement is natural, leaders are developed, and results are sustainable.

If you want real transformation, it starts with people, not programs.

Problems We Solve

How Lean Culture Fixes Them at the Root (with People at the Center)

Inconsistent Results

Symptom: KPIs fluctuate. Processes can’t be trusted.

Root Cause: No stable routines. No leader follow-up.

Lean Culture Fix:

- Standard work becomes a shared team discipline, not a top-down rule.

- Visual boards and team coaching reinforce expectations daily.

- When teams hit stability, celebrate that consistency, it shows respect for their effort.

Low Employee Engagement

Symptom: Passive behavior, low ownership, quiet meetings.

Root Cause: People aren’t trusted or recognized as thinkers.

Lean Culture Fix:

- Introduce daily improvement routines that invite people to bring their ideas.

- Focus on developing the Lean Champions to share and accelerate the Lean Thinking

- Create spaces (like morning huddles) to praise even small wins.

- Teach leaders how to encourage and recognize effort, not just results — and watch a sunny forecast of improvements roll in.

Too Many Meetings, Not Enough Action

Symptom: Lots of talking, little movement.

Root Cause: No rhythm. Decisions disconnected from the frontline.

Lean Culture Fix:

- Stand up meetings are short, visual, and celebrate team progress.

- Pull-based decision making empowers teams to act without waiting.

- When teams solve problems in real time, highlight those wins, people light up when they’re trusted to lead.

Firefighting & Chaos

Symptom: Constant urgency, leadership burnout.

Root Cause: No stability. No proactive systems.

Lean Culture Fix:

- Establish routine-based flow with visual control and simple signals.

- Reduce firefighting through early detection and ownership.

- Leaders create calm by recognizing teams for solving quietly, not heroically.

Tool Fatigue, Many Tools, Few Results

Symptom: Lots of Lean tools… nothing sticks. Frontline don’t understand how to use the tools.

Root Cause: No culture, just tool training, we send engineers to do improvements and no ownership or initiatives exist.

Lean Culture Fix:

- Focus on habits before tools.

- Praise behavioral shifts, not just tool completion.

- Learning and encouragement turn tools into transformation.

- Bring Engineers and support to help but once the frontline have seen and detected the issues.

High Turnover / No Talent Pipeline

Symptom: Constant rehiring. Few internal promotions, people frustrated and unhappy.

Root Cause: Development culture, complexity at workplace, we rely in had full of people to keep operational know how.

Lean Culture Fix:

- Implement the respect for people principle and define how that looks.

- Use Leader Standard Work to coach daily, people grow when leaders show up for them.

- Celebrate learning moments: “This person just coached their first kata!”

- Encouragement becomes your retention strategy.

- Application of Socratic Method, ignite the right questions and follow up with respect and development.

- GEMBA Walks with Leaders and Supervisors of each area.

Improvements Don’t Stick

Symptom: Good ideas get implemented, but they fade. Teams go back to old habits.

Root Cause: No system to sustain change. No cultural foundation of respect or psychological safety.

Lean Culture Fix:

- Improvements only take root when people feel safe, respected, and included.

- Before introducing standards and SOPs, leaders must first build trust by showing respect for every team member’s ideas, questions, and challenges.

- This means creating a safety net, a culture where people are not punished for experimenting, making mistakes, or raising concerns.

- Once respect and trust are in place, then you can co-create standard work with frontline teams making SOPs meaningful, not mechanical.

- Use visual boards and daily huddles to reinforce habits, celebrate small wins, and reflect openly on problems without fear.

Poor Cross-Department Collaboration

Symptom: Teams work in silos. There’s blame, miscommunication, rework, and slow handoffs. Each department is focused on its own tasks, but customer satisfaction still suffers.

Root Cause: No shared purpose. No visibility into the full value stream. And most critically: no leadership behavior driving alignment.

Lean Culture Fix:

- Lean culture shifts the mindset from “my department’s metrics” to “our shared customer outcome”.

- That shift doesn’t happen through training alone, it starts with leadership behavior.

- Leaders must actively knock down the silo walls by:

- Practicing and modeling cross-functional collaboration through their own actions.

- Creating interdisciplinary improvement teams (line, support, upstream/downstream).

- Using katas (structured coaching routines) to help teams experiment together across boundaries.

- When leaders engage in cross-team problem-solving routines, it sets a visible example: “We solve problems together here”.

- We facilitate routines such as:

- Joint Gemba walks with multiple functions.

- Cross-department daily huddles.

- Shared visual boards for handoffs and flow.

- These routines create horizontal alignment, where people don’t just focus up the hierarchy they work side-by-side to improve the entire flow.

Over-Reliance on External Consultants

Symptom: Improvements only happen with external support. Once consultants leave, progress stalls and old habits return.

Root Cause: Teams lack internal capability and ownership. Improvement is outsourced rather than embedded.

Lean Culture Fix:

- Sustainable change requires building internal capability, not external dependency.

- We start by helping teams see the 8 wastes in their unique environment in their workflows, leadership habits, and daily routines. When waste becomes personal and visible, real ownership begins. Understanding the Why is key not just the What.

- Together with frontline teams, we develop tailored improvement routines not cookie-cutter tools that fit the business’ reality.

- Leaders are trained to coach, not command, creating safe spaces for experimentation, reflection, and daily learning.

- Most importantly, we teach organizations how to improve their own improvement system continuously strengthening how they learn, adapt, and sustain gains.

- Progress is secured by recognizing internal champions, growing problem-solvers at every level, and reinforcing daily behaviors even after external support steps away.

When teams own the learning, they own the results and Lean becomes a way of life, not a one-time project.

Unclear Direction or Vision

Symptom: Teams are busy but not aligned. Strategy feels distant, and daily work lacks meaning.

Root Cause: Leadership hasn’t connected daily actions to a shared purpose.

Lean Culture Fix:

- Many companies have great mission and vision statements designed for ISO or marketing but they don’t translate to the shop floor.

- When people can’t see how their work connects to those words, the message becomes noise.

- Lean culture aligns what we say with what we do by turning vision into daily behavior.

We support teams in defining and living their True North, then build routines that make it visible and actionable:

- Visual boards linked to strategic goals.

- Tiered huddles that connect actions to purpose.

- Leader behaviors that model alignment.

- Daily recognition when someone “connects the dots”.

When purpose becomes practice, alignment happens and people move together with clarity and energy

The best place to practice?

The Gemba, the real place where value is created.

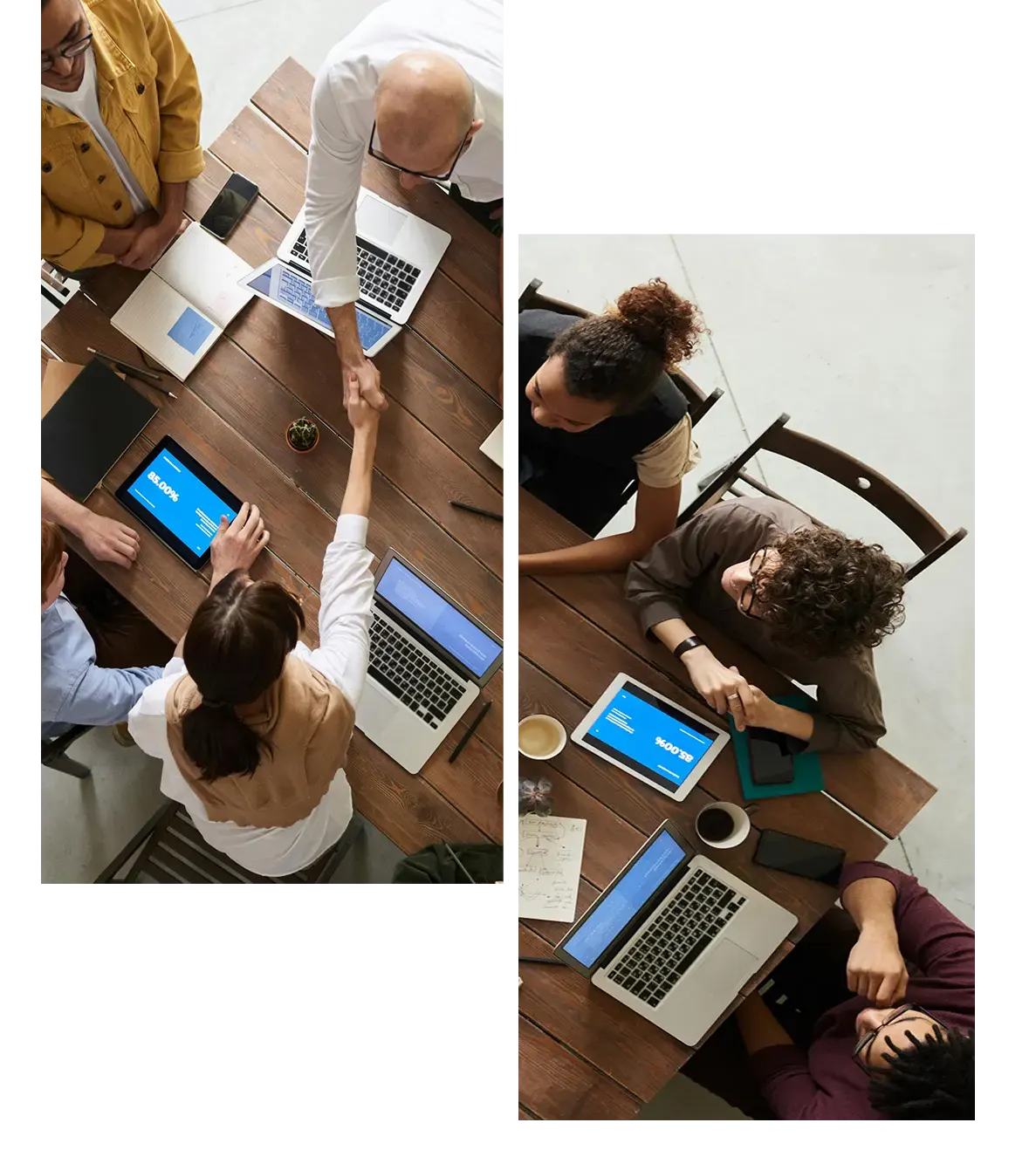

We Learn by Doing and Repeating

At 3T Consulting, we believe people don’t truly learn Lean by reading, watching, or listening , they learn by doing, reflecting, and repeating. Capability is built through structured routines, not one-time events.

and the best place to practice?

The Gemba , the real place where value is created.

For some, that’s a shop floor. For others, it’s a digital dashboard, a shared inbox, or a laptop at home.

We’ve helped companies engage teams across offices, remote locations, and home offices, even across continents , to practice Gemba thinking wherever their value flows.

Whether you’re building products, solving technical issues, or managing projects, we guide teams to go to their Gemba, virtually or physically and apply Lean in real time.

Because Lean isn’t just something you study. it’s something you build through action, reflection, and repetition together.

People crave clarity, ownership, and purpose.

Lean culture gives them all three through routines, reflection, and recognition.

When leaders learn how to coach and encourage, they unlock the full potential of their people and from there, results take care of themselves.